Now that we have 2D contour plots of the energy ranges emitted by the bulbs at different distances/locations, we need to turn those plots into 3D models. We also need to 3D model the actual masks that will be sanitized so we can intersect the UV-C bulb energy model with the mask model to determine how much mask surface area each energy range covers at a given position (yes!). From various projects over the years, I ended up with an assortment of a couple of leftover N95 and N100 disposable masks. I 3D modeled the 4 mask types above using Solidworks.

Next after cleaning up a bit first in Illustrator, I imported the SVG vector lines from the 2D contour plots into Solidworks and extruded them. I made sure to curve them from the center to the ends of the bulb in order to account for the power drop off I also measured. I then colored each contour section to match the 2D plot colors to easy lookup as shown in the images above. With my 4 different size/shape mask models I was able to determine the closest distance possible to the bulb while being able to rotate the mask and keep from hitting the bulb, which turned out to be about 85mm (more on that in a subsequent post, but I intend to have the mask rotating and moving up/down in the chamber for maximum UV-C coverage).

Now that we have the distance between the mask and the bulb, we need to determine how much energy reaches the mask surface when the mask is at different angles relative to the bulb (simulating movement in the chamber). I measured the energy received by each of the 4 different masks in 3 configurations: Bulb perpendicular to the front of the mask, ~70 degrees to the side, and 45 degrees to the side while also being 30 degrees raised. As you can see in the above images, I am showing the intersections between the 3D mask models and the bulb output range 3D model. I then used the measuring tool to measure each of the cut surfaces in the bulb model to determine how much area in that particular energy band range gets to the surface.

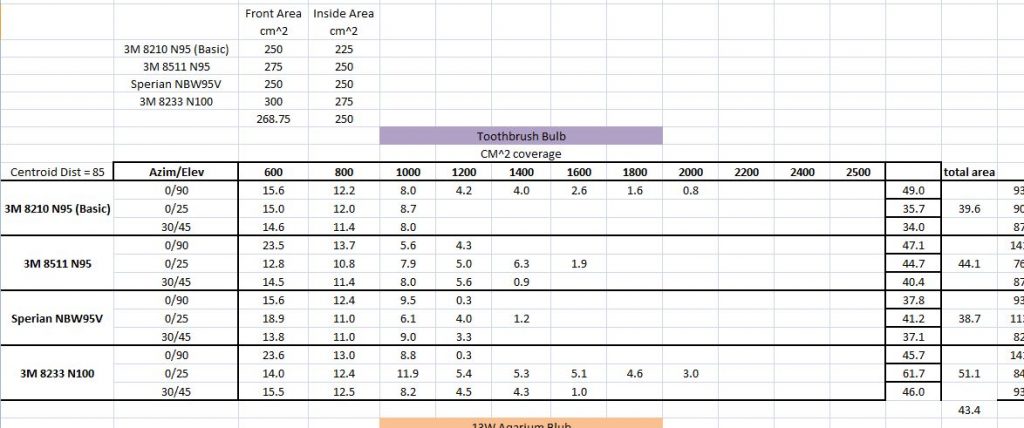

I then take all that surface area and energy data, for all the different bulb position conditions and mask types, and determine a nice weighted average energy output in the average weighted coverage area. The above image is an excerpt of these calculations. The Toothbrush bulb outputs an average of 0.85 mW/cm^2 in an average mask coverage area of 43.3 cm^2. The Aquarium bulb outputs 2.50 mW/cm^2 in an average mask coverage area of 211.4 cm^2.

Now since I modeled all the masks, I know the total area of the front and inside surfaces that need to be sanitized. With the initial requirement of 1 J/cm^2 to sanitize a mask, and with all this data I can calculate the time it will take to get 1 J/cm^2 to all surfaces of the mask. For the small toothbrush bulb this comes to 2 hours and since there are two sides (due to the rotation I plan on having), we double this number for a total of 4 hours required to clean an N95 mask with this bulb. For the large Aquarium bulb it comes to 8.5 minutes per side, so doubling that is only 17 minutes to sanitize an N95 mask! Given that the aquarium bulb is much more powerful and covers much more area, I will proceed with using this for my automated UV-C mask cleaning chamber.