I had an excellent time at this years New York Maker Faire! I saw some really cool stuff and met some really cool people. Here are some pics of the booth with my printer:

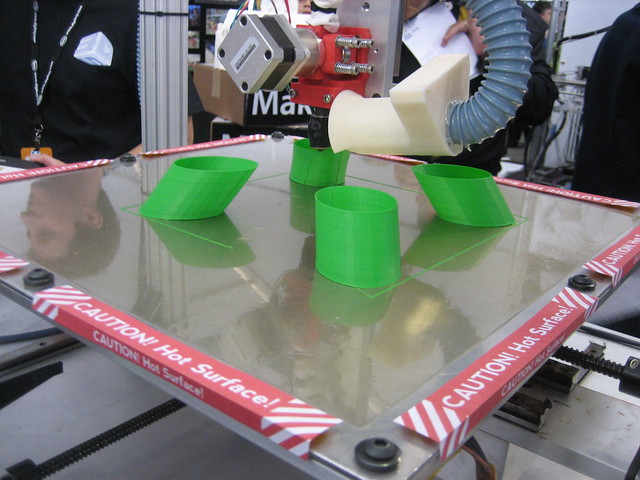

My Printer in the Booth, with my huge Printed Part

The printer looks kinda small when it’s out in the open doesn’t it?

Each day of the show I printed 1/4 of my big part

There was a cool breeze each day which kept my heated bed around 104°C, luckily we were under a tent as it could have been worse.

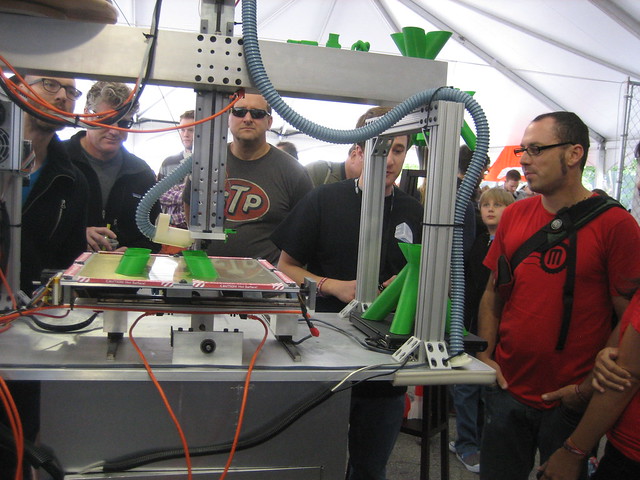

People Crowded around my printer

As with every Maker Faire I attend, I completely lost my voice by the end of the second day talking constantly to so many people!

Come to the NYC Maker Faire this weekend (September 17th and 18th) to see me and my printer in action at the 3D Systems booth!

I recently printed what I believe is the largest single part printed by a custom designed, RepRap based, home-built 3D printer. The part measures 376 x 376 x 250mm [14.80 x 14.80 x 9.84in] and took just under 2 days to print with a .25mm layer height. More info/specs, lots of pics and a sweet time lapse video of the build are below.

I used Solidworks to design this cool looking part so that it would max out my build volume on the printer. The part was designed and printed hollow, with a single wall thicknesses (0.5mm) and is made of fully recyclable ABS plastic (for example this is basically the same plastic LEGOs are made from). By printing the part hollow, as opposed to a complete solid, the part is much less likely to warp during printing. In fact, this part did not warp at all. It came out quite nicely and only required minimal clean-up with an exacto knife.

Here are some specs of the print from Skeinforge (The program that slices the 3D model and generates machine commands):

Extent

X axis extrusion starts at -188 mm and ends at 188 mm, for a width of 376 mm.

Y axis extrusion starts at -188 mm and ends at 188 mm, for a depth of 376 mm.

Z axis extrusion starts at 0 mm and ends at 318 mm, for a height of 318 mm.Extruder

Build time is 57 hours 37 minutes 32 seconds.

Distance extruded is 3112504.4 mm.

Distance traveled is 4144655.0 mm.

Extruder speed is 9.8

Extruder was extruding 75.1 percent of the time.

Extruder was toggled 41094 times.

Operating flow rate is 1.5 mm3/s.

Feed rate average is 20.0 mm/s, (1198.7 mm/min).Filament

Cross section area is 0.077 mm2.

Extrusion diameter is 0.31 mm.

Extrusion fill density ratio is 0.61Material

Volume extruded is 238.7 cc.Meta

Text has 3445976 lines and a size of 165227.0 KB.

Version is 10.11.05Slice

Layer thickness is 0.25 mm.

Perimeter width is 0.5 mm.

Based on the extruded volume, 238.7cc, this part cost me roughly $5 USD worth of ABS plastic. As for machine electricity costs, we can round up that the machine uses 0.5kWh, so running for around 48 hours will cost approximately $2.50 USD at $0.10/kWh. So a very rough estimate for the total cost of this print is $7.50 USD. You will also notice that the part was supposed to print for a little longer and was supposed to be a little taller, but unfortunately, after approximately 48 hours of continuous printing, the plastic extruder jammed. Hey, it took a lot of work to get to this point and it’s still a pretty big print! :P