Over the summer, I had been getting a lot of requests from friends for new bottle openers as I had given them out last summer. With my new higher resolution extruder I was able to make far better quality openers than last summer. On the side of the opener I put the shape of Long Island, and it came out excellent, even with all the thin and jagged sections. My first attempt (below) was to try and print 25 at a time using the skeinforge multiply tool.

This did not work too well, as the openers started warping pretty early (as compared to a single opener print with no warping). Since the base is square to the nozzle and the bed heat is fairly uniform throughout, this could be attributed to that fact that each layer takes basically 25 times longer to print because I am printing 25 at a time in parallel (i.e. there is a much larger gap in time between layers being printed on a single opener).

He is a smaller print with 10 openers in parallel. They were able to finish, but almost all were very warped. So I thought that if 1 bottle opener printed at time comes out great, why not just print in series? It takes basically the exact same amount of time.

Here are 8 bottle openers being printed in series. All it took was some copy/paste of the gcode for a single print, with some offsets so the nozzle did not crash into an already finished print. This method worked excellent.

I ended up printing somewhere around 40 openers with this series method. The most I made in one print was 16 at a time. They came out great and you can see the detail of long island in the above image.

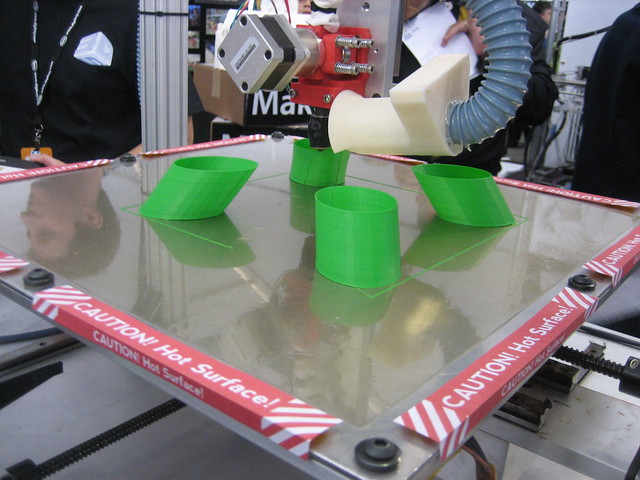

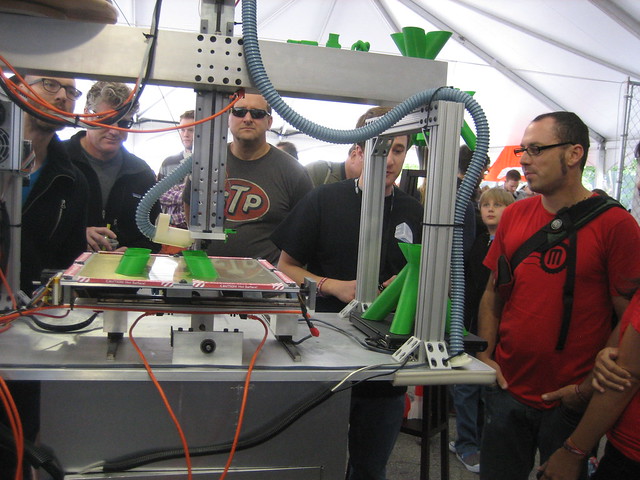

I had an excellent time at this years New York Maker Faire! I saw some really cool stuff and met some really cool people. Here are some pics of the booth with my printer:

My Printer in the Booth, with my huge Printed Part

The printer looks kinda small when it’s out in the open doesn’t it?

Each day of the show I printed 1/4 of my big part

There was a cool breeze each day which kept my heated bed around 104°C, luckily we were under a tent as it could have been worse.

People Crowded around my printer

As with every Maker Faire I attend, I completely lost my voice by the end of the second day talking constantly to so many people!

Come to the NYC Maker Faire this weekend (September 17th and 18th) to see me and my printer in action at the 3D Systems booth!