Now that we have 2D contour plots of the energy ranges emitted by the bulbs at different distances/locations, we need to turn those plots into 3D models. We also need to 3D model the actual masks that will be sanitized so we can intersect the UV-C bulb energy model with the mask model to determine how much mask surface area each energy range covers at a given position (yes!). From various projects over the years, I ended up with an assortment of a couple of leftover N95 and N100 disposable masks. I 3D modeled the 4 mask types above using Solidworks.

Next after cleaning up a bit first in Illustrator, I imported the SVG vector lines from the 2D contour plots into Solidworks and extruded them. I made sure to curve them from the center to the ends of the bulb in order to account for the power drop off I also measured. I then colored each contour section to match the 2D plot colors to easy lookup as shown in the images above. With my 4 different size/shape mask models I was able to determine the closest distance possible to the bulb while being able to rotate the mask and keep from hitting the bulb, which turned out to be about 85mm (more on that in a subsequent post, but I intend to have the mask rotating and moving up/down in the chamber for maximum UV-C coverage).

Now that we have the distance between the mask and the bulb, we need to determine how much energy reaches the mask surface when the mask is at different angles relative to the bulb (simulating movement in the chamber). I measured the energy received by each of the 4 different masks in 3 configurations: Bulb perpendicular to the front of the mask, ~70 degrees to the side, and 45 degrees to the side while also being 30 degrees raised. As you can see in the above images, I am showing the intersections between the 3D mask models and the bulb output range 3D model. I then used the measuring tool to measure each of the cut surfaces in the bulb model to determine how much area in that particular energy band range gets to the surface.

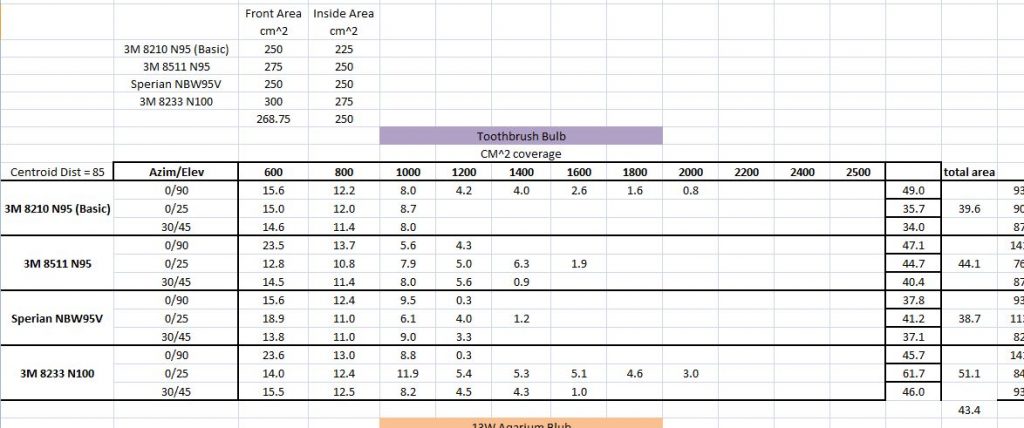

I then take all that surface area and energy data, for all the different bulb position conditions and mask types, and determine a nice weighted average energy output in the average weighted coverage area. The above image is an excerpt of these calculations. The Toothbrush bulb outputs an average of 0.85 mW/cm^2 in an average mask coverage area of 43.3 cm^2. The Aquarium bulb outputs 2.50 mW/cm^2 in an average mask coverage area of 211.4 cm^2.

Now since I modeled all the masks, I know the total area of the front and inside surfaces that need to be sanitized. With the initial requirement of 1 J/cm^2 to sanitize a mask, and with all this data I can calculate the time it will take to get 1 J/cm^2 to all surfaces of the mask. For the small toothbrush bulb this comes to 2 hours and since there are two sides (due to the rotation I plan on having), we double this number for a total of 4 hours required to clean an N95 mask with this bulb. For the large Aquarium bulb it comes to 8.5 minutes per side, so doubling that is only 17 minutes to sanitize an N95 mask! Given that the aquarium bulb is much more powerful and covers much more area, I will proceed with using this for my automated UV-C mask cleaning chamber.

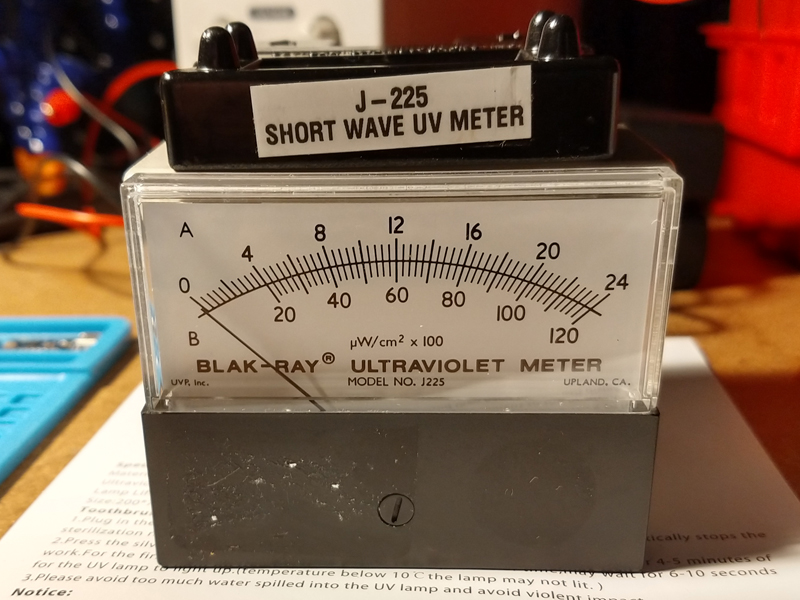

A way to measure the UV-C energy was needed calibrated to the correct wavelengths. I have used Ophir Starlite digital power meters in industry in the past with Lasers and LEDs for wavelengths in and around this range, but they are prohibitively expensive. Luckily I came across the BLAK-RAY J-225 Short Wave UV meter which specifically meant for measuring UV-C bulb power output (pic above). Its measurement sensitivity range is from 220nm-290nm with peak sensitivity at 254nm, which is just what I need. You can find lots of these units used on eBay. I was able to find one in great shape with a relatively recent calibration for only $40!

It is a neat little analog device, and seems to be self-powered. The measurement probe is on top of the unit and has a rectangular area that collects the UV-C light. This probe is actually removable and can be connected with simple banana jack cables for remote use in smaller areas. Output is measured in micro Watts per square centimeter. There is a switch on top of the unit to switch between the A (top) and B (bottom) measurement ranges on the analog meter.

To make a contour plot of the energy emitted from the bulbs, I made a semi-circle pattern and printed it out with 22.5 degree radials with 10mm spacing along each up to 100mm. I placed this pattern on my little flat granite block measuring surface plate and put the bulb at the center as shown in the images above. I mounted the UV-C probe onto a small linear translation slide so I could adjust the Z height if needed. I then moved the probe to the 90 points and manually recorded them in excel.

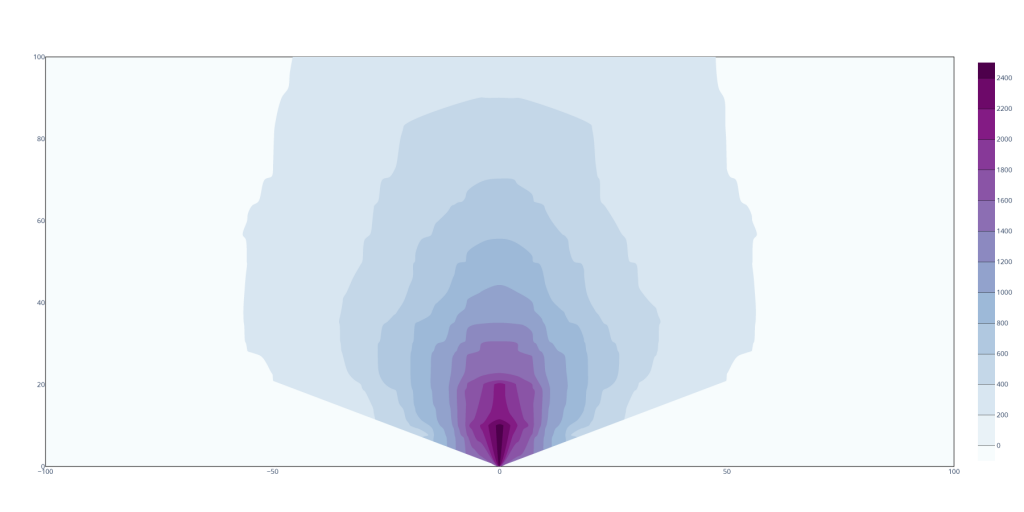

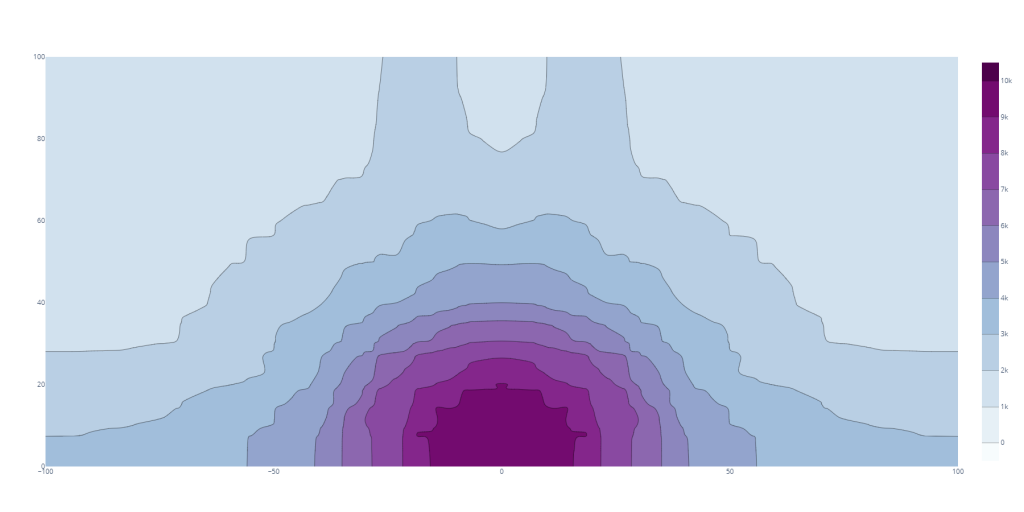

The 90 data points were laid out in a table at their respective X and Y coordinates. Unfortunately when making contour plots in Excel, it cannot automatically fill-in/interpolate data between X/Y points, so the plot does not really work. So I turned to the really awesome python program, Plotly. With a lot of massaging of the data first in Excel and Notepad++, I was able to modify one of their online contour plot demos with my data to produce the really nice plots below. Also Plotly lets you save plots as vector SVG file format, which helps a lot to make 3D CAD model of the out energy; more on that further down.

Above is the contour plot of the Toothbrush bulb with reflector. The X and Y axes are position distance in mm, intensity scale on right side is μW/cm^2. I cleaned up the reflector path since light will be blocked directly to the right and left of the bulb. There is approximately a 12.5% drop off in power between the mid plane Z-height of the bulb and the ends.

Above is the contour plot of the Aquarium Lamp. This bulb has significantly higher output than the toothbrush bulb. The X and Y axes are position distance in mm, intensity scale on right side is μW/cm^2. The Lamp is a cylinder so the output is even radially (I did not clean this up here in the 2D plot, but I did in the 3D CAD). There is approximately a 33.3% drop off in power between the mid plane Z-height of the bulb and the ends.

Given the current shortage, extending the usable life of existing disposable N95 respirators is one of the very highest priorities. One of the most effective and rapidly deployable methods is to expose the masks to a measured amount of UV-C radiation.

A number of papers were published after the first SARS outbreak many years ago on how to decontaminate N95 masks in order to prolong their usable life during a future pandemic outbreak and supply shortage. Below is a listing of relevant papers on this decontamination concept as well as a summary New York Times article. Somewhat ironically, a number of these older papers cite that we need to take steps to increase our emergency stockpile of N95 masks for a future outbreak.

You can download all of these papers here: UV-C Papers

A summary New York Times article can be found here

A number of the papers detail experimentally measured required UV-C wavelength energy and soak times to fully decontaminate the masks. Typically the consensus it that masks need to be exposed to at least 1.0 J/cm^2 centered around 254nm wavelength in order to be fully decontaminated. Another paper discusses the structural integrity of N95 respirators after UV-C radiation and finds that they are still effective at filtering particles, though depending on manufacturer, may have a limit to how many times they can be cleaned before the materials begin to breakdown. The last two papers are were written recently as a response to the pandemic to summarize and steps on decontamination methods.

My goal is to create a rapidly depolyable, low-cost, and 3D printable UV-C N95 Mask decontamination chamber with a measured output to conform to the 1.0 J/cm^2 UV-C requirement.

Germicidal Wavelengths fall generally in the 200nm-300nm range. The vast majority of Germicidal Sanitizing lamps emit peak energy around the center of that range at 254nm. Note: Your typical UV curing oven for photocurable resin 3D Printers (SLA, etc), and nail salon curing lamps, emit only within the UV-A and UV-B ranges and thus they will not disinfect anything.

UV-C light Safety Warning – UV-C light is very harmful to your vision, even for short periods of time. Always wear safety glasses that filter out these wavelengths. I have a pair of UVEX-S1933X which are inexpensive and readily available and have measured data on the specific wavelengths they filter out, (enlarge the above picture). Also it can be harmful to your skin like other UV wavelengths, so it is a good idea to wear long sleeves, and gloves when handling active bulbs for long periods of time.

Ozone Safety Warning – Ozone is very bad to breathe and will harm your lungs. It has a very distinct smell. Ozone is produced around 185nm wavelength. Cheap Low-Pressure Mercury Vapor UV-C Lamps emit a range of wavelengths centered around 254nm including wavelengths around 185nm. Higher quality mercury vapor lamps have AR coatings to filter out these ozone producing wavelengths. Here is a great summary Article from the EPA on the dangers of breathing in Ozone. If you are using one of these cheap bulbs that produces Ozone, and you will definitely be able to smell its unique smell, be sure to test it outside or with a externally venting fume extractor.

There are generally two common bulb types that can emit light in the UV-C range: Low pressure Mercury-Vapor Lamps and LED. Mercury Vapor lamps are the most common and have been around a long time. They are available in a wide range of shapes and sizes and typically use higher voltages to excite the gas in the quartz tubes (sort of like florescent bulbs). These lamps emit a wide range of wavelengths but the peak energy emitted is centered around 254nm. LEDs that emit in this wavelength are a relatively newer technology and are thus much much more expensive. These LEDs produce a very very narrow wavelength range and are “binned” (sorted) for their peak wavelength output. They are also generally have much lower power than the gas lamps, so many will be needed to achieve the same effect. UV-C range LEDs increase in ubiquity, volume and thus price every year. So eventually they will likely overtake the mercury vapor lamps.

I will focus on low pressure mercury vapor lamps thier cost/ubiquity and also lamps that come with their own power supply (for ease of integration).

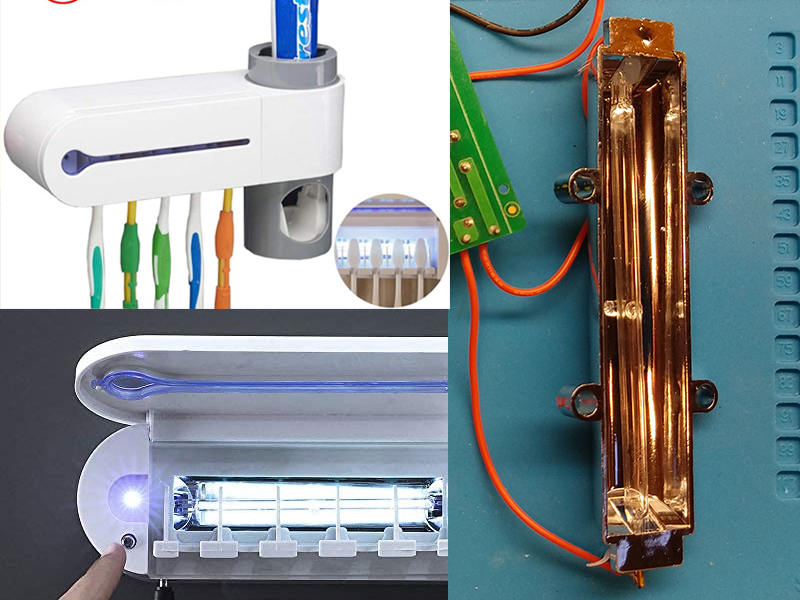

The above Toothbrush Sanitizer is available across the internet in various versions for around $20. I chose it for the bulb size ~100mm long. It also came with a 9v power supply and I could possibly reuse the internal PCB and modify its decade counter timer. The bulb is integrated into a nice reflector for focusing the energy. One drawback is that this cheap bulb emits lots of Ozone.

I later found that there are much larger Aquarium Sanitizer UV-C lamps available in a range of sizes. I bought the highest power version I could find on eBay pictured above (13W) for around $15. It comes with its own ~36v DC power supply. I do not smell any obvious ozone, so I think it may have an AR coating.